XPS Extrusion Polystyrene Foam Sheet Production Line

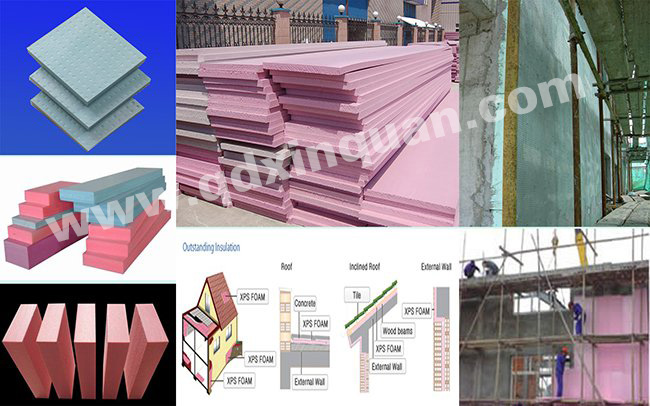

1. XPS Foam Sheet Features:

XPS extruded polystyrene foam sheet, also known as polystyrene extruded sheet, (referred to as XPS); has a closed-cell honeycomb structure, and is superior to other types in terms of density, water absorption, thermal conductivity and vapor permeability coefficient. Therefore, it has the characteristics of good strength, light weight, airtightness, corrosion resistance, anti-aging and low price. decoration, etc.

◎ It is used for steel structure workshops, iron houses and colored corrugated tiles to keep warm;

◎ It is used for heat preservation and waterproofing of freezers.

◎ It is used for cushioning under the roadbed to control the freeze-swell of the ground; ◎ It is used for

waterproof and thermal insulation of walls and roofs of residential buildings, office buildings, factories;

Functions;

◎ Used for central air-conditioning ventilation ducts, which play the role of heat preservation and heat insulation.

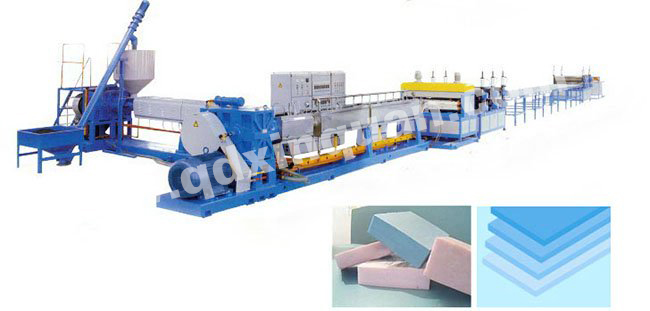

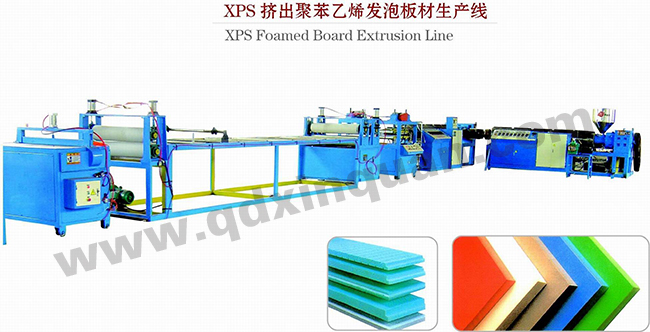

2. Introduction of XPS foam board equipment:

The screw and barrel of the extruder is uniquely designed for XPS foaming, and the extrusion volume is large and stable; the automatic feeding system is accurate and stable; and the high-speed screen changer and metering pump are used to ensure the average extrusion of the plastic after melting, so that the product The thickness is even and flat.

3. Main technical parameters:

| machine type | SMXPS-135/150 | SMXPS-150/170 | SMXPS-170/200 | |

| Screw diameter (mm) | ¢135/150 | ¢150/170 | ¢170/200 | |

| Heating power (kw) | 50 52 | 58 68 | 78 100 | |

| Driving power (kw) | 75 90 | 90 110 | 110 132 | |

| Product thickness (mm) | 20-80 | 20-100 | 40-120 | |

| Product width (mm) | 600,900 | 600,900,1200 | 600,900,1200 | |

| Product length (mm) | 1200,1250,2450,2500 | 1200,1250,2450,2500 | 1200,1250,2450,2500 | |

| Production capacity (kg/h) | 280-320 | 300-360 | 380-500 | |

| Installed power (kw) | 300 | 380 | 400 | |

| product edge | SS flat head |  |

||

| SL lap |  |

|||

| RC Rain Gutter |  |

|||