PP Hollow Grid Board Production Line

1. About PP hollow grid board equipment:

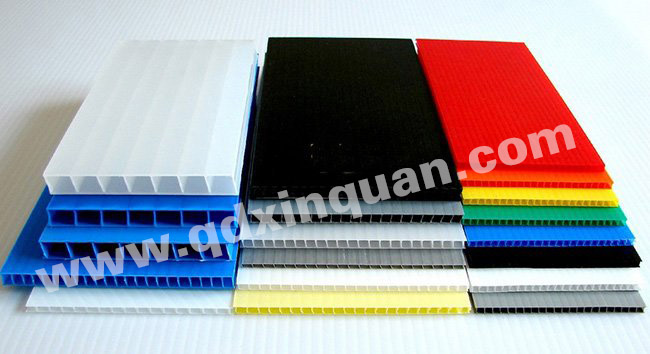

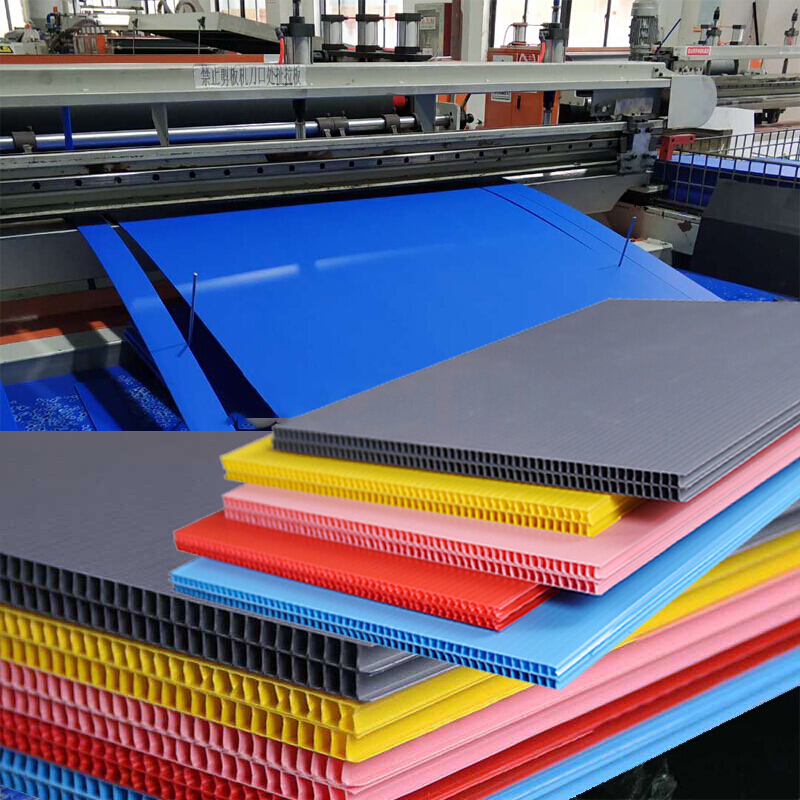

The equipment is mainly used for the production of PP hollow lattice sheet. PP grating thickness 2-14mm, 1220-2600mm.

The production line mainly includes:

Extruder : The screw is specially designed for venting, and the advanced PLC temperature control system ensures good plasticization of plastics and stable extrusion with high output.

Screen changer : Hydraulic quick screen changing device is used to make the screen changing process fast and effective; double station and special sealing structure ensure stable operation of the screen changer

Mould : The mould is made of high-quality alloy steel, with a highly active throttling device, so that the pressure of the material flow in the die is uniform and uniform; the differential adjustment of the upper and lower dies ensures the uniform thickness of the upper and lower walls.

Vacuum setting table : The setting system is equipped with a fast heat exchange refrigeration system, which is effectively interleaved with the vacuum system and distributed sequentially. This distribution ensures the setting accuracy. The vacuum system consists of two independent subsystems, each of which is equipped with multiple three-point fixed cycle vacuum lines, and each fixed cycle carries a vacuum adjustment system and a vacuum display system, so that the vacuum degree on the surface of the plate is uniform and stable .

Tractor : There are first and second groups of tractors. The first group of tractors is of high power, large reduction ratio, and multi-roller type. It has excellent low-speed operation performance and large traction, and can synchronously and evenly remove the sheet from the vacuum setting table. pull out. The second group of tractors is treated for stress relief. It is also equipped with a trimming device to ensure the effective width of the board and the quality of the edge of the board.

Stress reliever : The advanced large-area conduction heating method can effectively eliminate the stress of the plate and further improve the flatness of the plate.

Cutting machine : equipped with precise instant fixed-length cutting and automatic lifting and unloading device, special alloy wear-resistant blade edge, to ensure the quality of the cutting surface of the plate.

2. Technical parameters of PP hollow lattice sheet production line

| Extruder Specifications | PP SJ-110/36 | PP SJ-120/36 –SJ150/36 |

| main motor power | 75KW | 110-132KW |

| Product width | 1300-1600mm | 1600-2600mm |

| Product thickness | 2-20mm | 2-6-10mm |

3. Product features and applications:

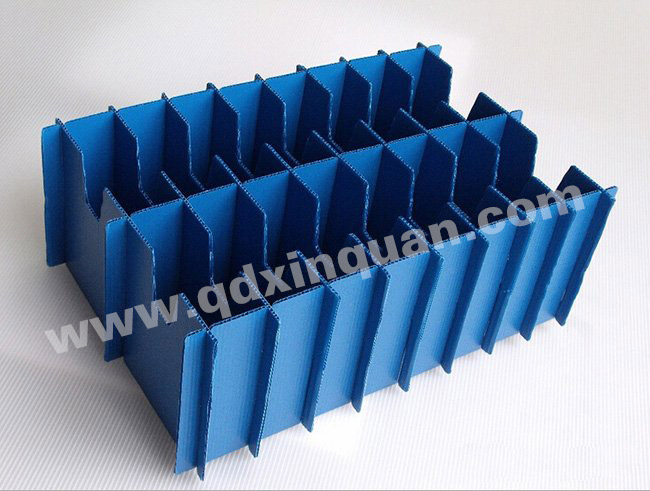

The PP hollow lattice board produced by our company’s equipment has light material, high strength, moisture resistance, smooth surface, good environmental performance and secondary processing performance. PP lattice board can be processed into turnover boxes, packing boxes, partitions, linings, pads Plates, bottom brackets, etc., are widely used in electronics, home appliances, luggage, machinery, postal services, food, medicine and advertising and decoration industries.

Remarks: The above specifications are subject to change without notice.